Our Capabilities As A Spline Gear Manufacturer

Are you looking for Internal and external splines ? Marshall makes both of these and can offer competitive rates for both Internal and External spline cutting.

-

Splines are used in mechanical rotating drive systems. Any device that transfers rotary motion from an input shaft to an output shaft most likely uses splines of one form or another.

-

A splined shaft is one that has equally spaced teeth around the circumference parallel to the shaft’s axis of rotation. These teeth can be straight sided, serrations or involute form.

-

The externally splined shaft mates with an internal spline that has slots, or spaces of a mating form to the shaft’s teeth.

The rotation of the splined shaft is transferred to the internally splined member, such as a gear or other rotary device. The spline connection provides an equally distributed load along the sides of the teeth. This shared load provides a longer fatigue life verses a keyway drive.

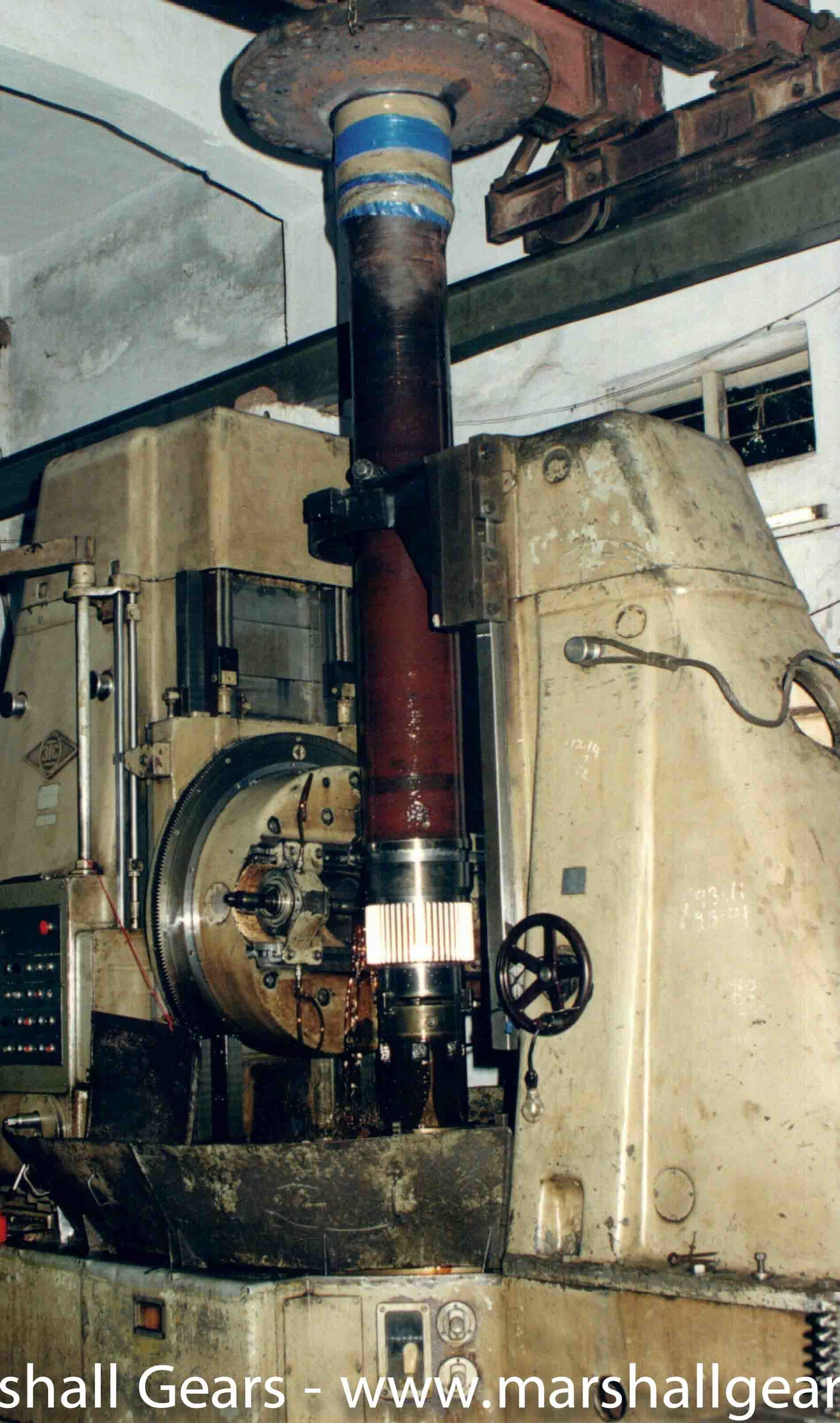

Involute and straight sided splines as well as serrations can be produced by hobbing, shaping and broaching processes. Both internal and external splines can be cut using our gear cutting machines, including internal straight spline and external straight and helical splines.

As A Spline Gear Manufacturer, We Manufacture The Following Types Of Spline Gears.

This type has equally spaced teeth that are straight sided. The teeth on the shaft have an equal tooth thickness at any point measured radially out from the axis of rotation. Conversely, the internal parallel spline has parallel spaces.

This type has equally spaced teeth, but they are not straight sided. The teeth have an involute form, similar to an involute gear tooth.We manufacture Pinions from forging materials like EN 9, EN 19, EN 24,etc.

We manufacture Pinions in all the standard and non standard modules right up to 50 Module.

We supply these to the Cement, Steel, Mining, Engineering, Marine, Sugar Industries.

This type of spline has a tooth form that is non-involute. The teeth of the male detail are in the form of an included angle, with the female serration having spaces of the same included angle.